What is mold making?

“Mold making” refers to the production of the molds needed to make castings from either metal or plastic. These molds make it possible to manufacture thousands of identical components – without any signs of wear or tear.

“Mold making” refers to the production of the molds needed to make castings from either metal or plastic. These molds make it possible to manufacture thousands of identical components – without any signs of wear or tear.

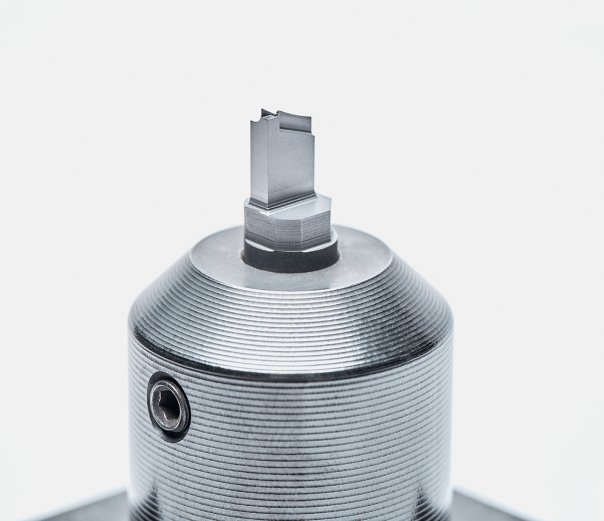

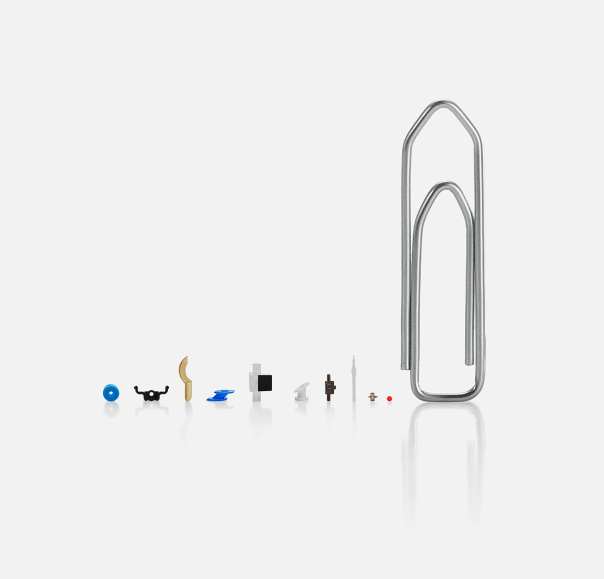

Medical components are complex per se and need to satisfy the most stringent quality and reliability requirements. Stamm AG is a specialist when it comes to the complex injection molded components used in medical technology, the manufacture of which requires tools that are extremely precise. In fact, as these molds contain up to 500 individual components, they’re even more complex and precise than the end products they’re used to create.

Designing and manufacturing the perfect mold is a process that not only requires in-depth expertise, but also patience, attention to detail and teamwork. It also calls for an understanding that the process represents an investment in the lifelong value of the product created by the mold.

Stamm AG has employees with decades of experience, which it leverages fully to the benefit of its customers. The entire team needs to collaborate very closely to analyze the design, find ways to optimize it and identify critical factors. From day one of the project, the individual departments (including design, mold making, production and quality assurance) provide input from many different perspectives. Innovative ideas, technical expertise and passion combine to create outstanding molds for the production of highly precise injection molded components.

Haste is the wrong approach when it comes to mold making. If the final result is a premium mold that can withstand millions of fillings without any reworking, then that patience has paid off. Because that’s the only way to guarantee quality throughout the entire process.

When manufacturing individual components and assemblies, SFS’s core technologies of cold forming, deep drawing and injection molding can often be combined. Different material properties open up a multitude of different possibilities when designing components and integrating various functions.

Comprehensive expertise is leveraged to create premium tailor-made products and smart solutions for customers. This goal hinges on embracing the right basic attitude: the never-ending desire to invent success together.

The smooth, efficient manufacturing process can be optimized by getting SFS on board at an early stage and through close cooperation with customers. The principles of Design for Manufacturing (DFM) support the development of the most highly precise medical devices and components found in the sector.