Many advantages are united in riveting, such as the overcoming of limited component accessibility or the permanent and secure joining together of the most varied materials, including sensitive ones. Blind rivets ensure the permanent joining together of even the most varied of materials. Blind rivet nuts are smart connection elements that create a highly stressable thread for a releasable connection, especially in thin workpieces that are only accessible on one side. All connectors are available in various versions, materials and shapes.

Riveting

Benefits

GESIPA® offers interesting solutions and real added value with innovative system technologies, decades of experience in the area of riveting and a wide range of connectors.

Riveting

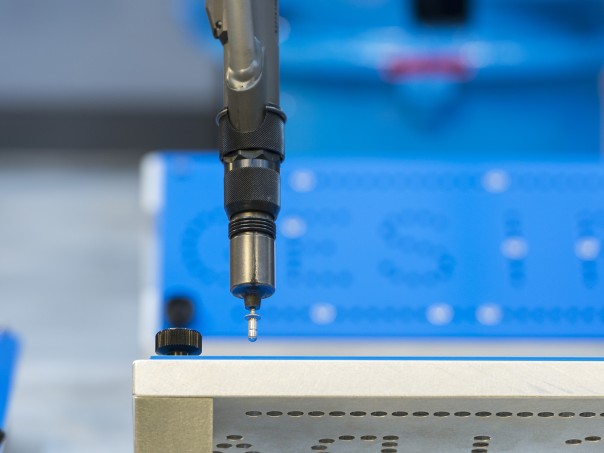

Blind rivet tool

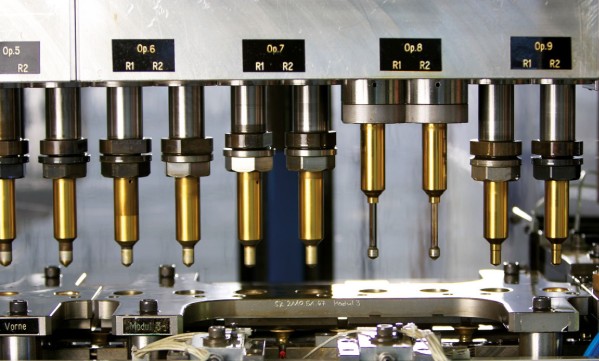

GESIPA® specializes in optimally adjusting the connection elements and processing devices, developed and produced in house, to the component specifications. Depending on the individual requirement, processing devices are developed and produced according to application, be it for blind rivets or blind rivet nuts. Furthermore, if required, process-monitoring processing devices can also secure and permanently document the quality of the connection.

WinTech – setting process monitoring

With the process-oriented setting tools, in the production of critical components or even automated setting processes, a check and documentation of the results can be realized. WinTech setting process monitoring is ideal for demanding fastening technology of safety-relevant components with planned break rivets.

Industry 4.0 by GESIPA®

The new generation of blind rivet processing allows a connection of the blind rivet tool with mobile end devices via an app. Networking offers a great deal of added value such as the checking of rivet processes, processing security, status and service displays as well as quick and simple access to operating, maintenance and repair guides; ultimately the optimization of the value added chain. Setting process assistant software is optionally available.

Fully automated rivet processing

The automatic processing of blind rivets and blind rivet nuts is especially suited to industrial use in large-scale production. Here the blind rivet tools are adjusted according to the customer requirements and can be easily installed in a robot application or used by an operator via the individual configuration.

Speed riveting technology

The speed riveting technology makes pre-magazine-loaded rivets available on a single-use mandrel for immediate use. The automatic feed of the magazine rivet allows particularly fast cycle times. The speed riveting technology represents an economical alternative to automation.

Solid riveting

The area of solid riveting produces solid rivets and semi-tubular rivets according to customer-specific requirements. The solid and semi-tubular rivets offer a technical and economical alternative to screw connections or other connection systems. Thanks to various measurements, materials and head shapes, as well as appropriately produced processing devices, countless application cases can be covered.