Valuable technology for modern medicine

Robotic-assisted surgery allows surgeons to perform minimally invasive surgery using a robotic arm to hold and maneuver the surgical instruments. The surgeon sits at a console that provides a magnified, high-definition 3D view of the surgical site and controls the robotic arm. This precise approach enables medical professionals to perform complex, yet accurate surgical tasks in confined spaces with smaller incisions than open surgery.

Precision with no room for failure

Robotic-assisted knee replacement

Our customer, a medical technology company, provides instruments used to repair, regenerate, and replace tissue. The company offers a robotic-assisted surgical system designed to assist orthopedic surgeons in knee replacement surgery, including a instrument for precise implant placement. Imaging technology and software algorithms provide real-time data and feedback during the surgery, enabling alignment with the patient’s specific anatomy.

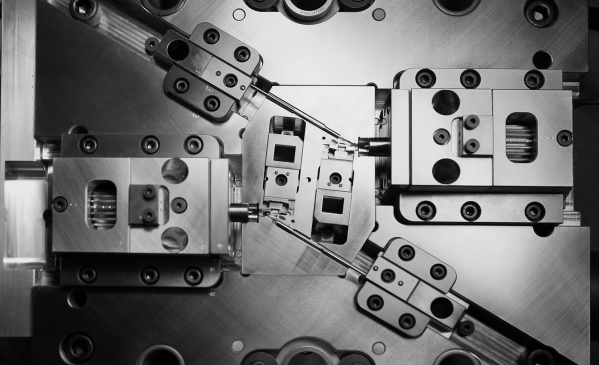

Tegra Medical, a member of the SFS Group, manufactures two of the system’s devices: a point probe used for calibration before the surgery and removed again afterwards, and femur and tibia trackers that fit into holders anchored to the bone itself.

Manufacturing expertise in complex devices

Tegra Medical has extensive experience in the manufacture of complex medical devices for minimally invasive orthopedic surgery. We have expertise in laser tube cutting and grinding, as well as the assembly of devices with intricate features.

Moreover, it is important for us to constantly invest in in advanced production equipment and processes. Tegra has installed laser tool checkers inside several machines to guarantee quality manufacturing. Laser beams are used to inspect the machines for chips, broken or damaged tools, and can indicate to the surgeon when to schedule downtime to replace worn-out parts.

Better outcomes for patient and surgeon

Less invasive surgery means less pain, reduced risk of infection, shorter hospital stays, and faster recovery time for patients. Since surgeons operate robotic systems from a console, using hand controls and foot pedals, the ergonomic advantages reduce potential strain and fatigue during long, complex procedures. Robotic systems can also be used to train new surgeons in a controlled environment under the direction of an experienced surgeon.

High quality medical devices manufactured using modern technology and processes lead to savings in materials and time during manufacture, improved durability of parts, and better long-term success.